Resistive Type

Window touch

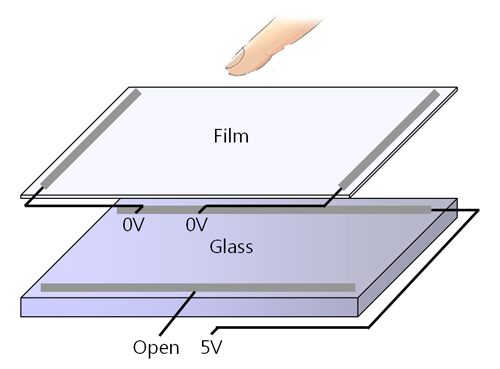

structure of the 4wire Resistive touch screen

- Top and bottom transparent conductive films are attached by double sided adhesive, Dot Spacers are placed with certain distance to prevent unnecessary short due to drooping of the top conductive film.

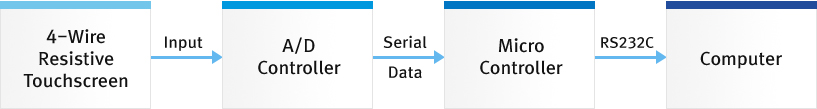

- Analog signal generated on the panel with touching is transmitted to controller through the FPCB.

Production method of the 4 wire resistive touch screen

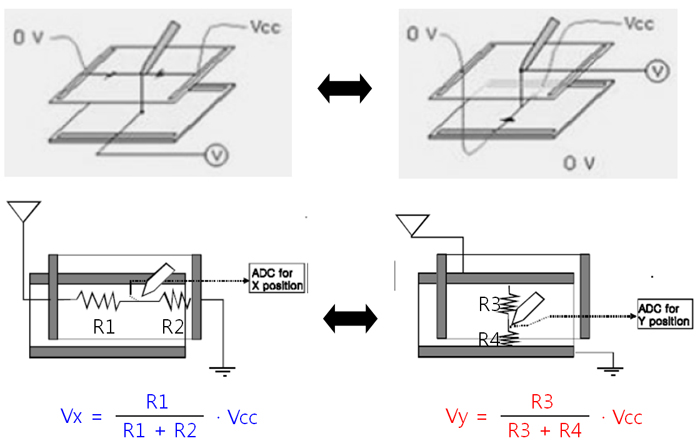

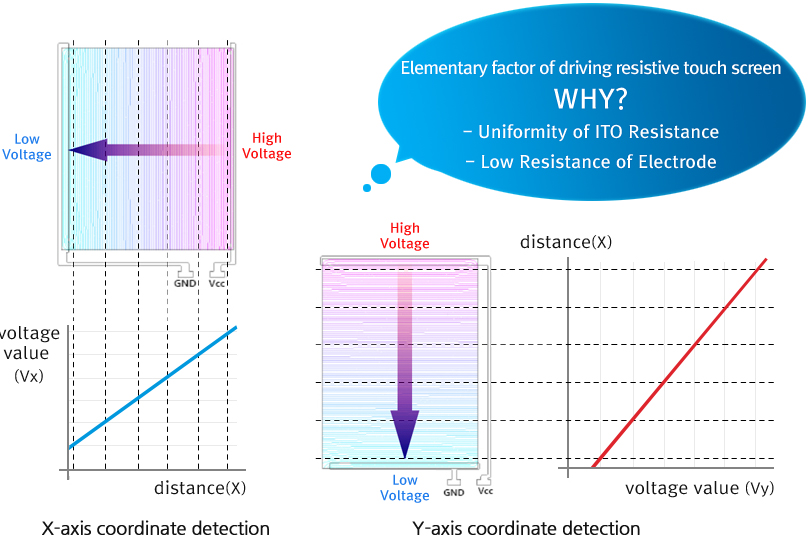

Driving principle of the 4 wire resistive touch screen

| 1. Apply power between Vcc and GND on the top and bottom respectively (Touch: top and bottom short) |  |

Touch Sensor/Controller |

| 2. X-axis voltage value Sensing and Digital change( X,Y operation signal Switching) | ||

| 3. Y-axis voltage value sensing and Digital change | ||

| 4. Data transmission |  |

Controller |

| 5. Displaying coordinate and Running event |  |

Driver |

|

||

- Standby condition : Vcc and GND is applied on the top and bottom respectively to wait for touching.

- X,Y driving signal switching and Coordinate detecting

- Equipotentiality : Constant and Continuos voltage change with being applied voltage on each X,Y-axis.

Window Type Touch Products

-

7”

7”

-

5”

5”

-

7”

7”

-

3.5”

3.5”

-

2.8”

2.8”

4 Wire Resistive Type Products Example

-

Window Touch for mobile phone

Window Touch for mobile phone

-

MP3

MP3

-

Mini PMP

Mini PMP

-

PND 5” ‘Strada Series’

PND 5” ‘Strada Series’

-

5” Panasonic AVN window touch

5” Panasonic AVN window touch

-

7” Panasonic AVN window touch

7” Panasonic AVN window touch

-

Kiosk in Tower Record

Kiosk in Tower Record

-

5.5” H/F/F/P type window touch - JVC IN-Dash Multimedia Receivers (KD-AVX77)

5.5” H/F/F/P type window touch - JVC IN-Dash Multimedia Receivers (KD-AVX77)